As magnet manufacturers, we often encounter the question of whether to use a Neodymium magnet or a Ferrite magnet for a particular application. At first glance, this may seem like a simple decision, but in reality, there are many factors to consider depending on the application’s specific requirements. These may include magnetic field strength, coercive force, miniaturization, cost, temperature tolerance, and many other considerations. By carefully weighing the pros and cons of each type of magnet, we can help our customers choose the most suitable magnet for their needs.

Brief Explanation Of Composition And Manufacturing Differences

Neodymium and ferrite magnets are made from different materials and have different manufacturing processes.

Neodymium magnets, also known as rare earth magnets, are made from an alloy of neodymium, iron, and boron. They are produced through a process called powder metallurgy, in which the raw materials are ground into a fine powder and then pressed and sintered (heated under pressure) to form a solid magnet. The sintered magnet is ground and finished to the desired shape and size.

Ferrite magnets, also known as ceramic magnets, are made from a mixture of iron oxide and other metallic elements. They are produced through dry pressing, in which the raw materials are mixed and then pressed into the desired shape and size. The pressed magnets are fired at high temperatures to harden them and improve their magnetic properties.

Should I Buy A Neodymium Magnet Or A Ferrite Magnet?

Depending on my goals for the product, I may choose to use either type of magnet, which could include cost, efficiency, weight, size, performance, form factor, aesthetics, lead time, and more.

For example, if efficiency is my top priority, I may opt for Neodymium magnets, which have a higher magnetic field per unit volume than Ferrite magnets. On the other hand, if cost is my main concern, I might choose Ferrite magnets, which offer a higher magnetic field per dollar spent compared to Neodymium magnets.

There are other factors to consider when making this decision, and it’s important to weigh them to make the best choice for the specific application.

Why Do I Choose Neodymium Magnets?

Several factors may favor using neodymium magnets over ferrite magnets in a particular application. These include:

- Higher magnetic field strength:

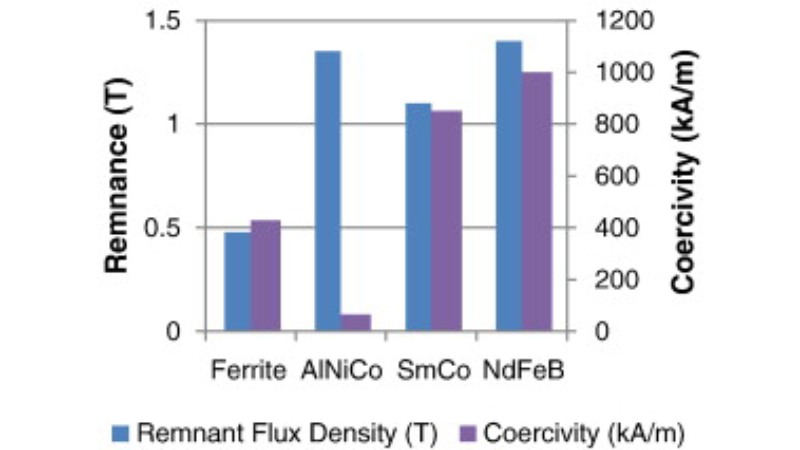

Neodymium magnets generally have the highest magnetic field strength of any magnet, making them suitable for applications that require a high magnetic field. For example, neodymium magnets are often used in motors and generators, where they can generate a strong magnetic field in a small size, resulting in smaller and more efficient motors.

Ferrite magnets have a lower magnetic field strength than neodymium magnets, making them less suitable for applications that require a high magnetic field. However, they may be a more cost-effective and temperature-tolerant option in certain cases.

- Higher coercivity:

Neodymium magnets generally have the highest coercivity of any type of magnet at room temperature and even at mildly elevated temperatures, up to 230 degrees Celsius. This means they are highly resistant to demagnetization in the presence of an opposing magnetic field, making them suitable for applications where the magnet may be exposed to other magnetic fields or external factors that could affect its magnetism.

Ferrite magnets also have a high coercivity, but they are generally lower than neodymium magnets. They resist demagnetization by external fields but may not be as resistant as neodymium magnets under certain conditions.

- Easier Machining:

Neodymium magnets are generally easier to machine than ferrite magnets due to their relative brittleness. Ferrite magnets are more brittle and harder, making them more difficult to machine to precise tolerances. This can increase the cost of ferrite magnets, especially for smaller parts with complex shapes.

However, it’s important to note that their ease of machinability does not solely determine the cost of manufacturing magnets. Other factors, such as material costs, manufacturing process, and demand, can also play a role in the overall cost of producing magnets.

- Better suited for miniaturization:

Miniaturization and size-related processing costs are essential when selecting a magnet for an application. A smaller magnet can minimize other components in the design, which may result in lower production costs. However, this depends on the particular design and the specific requirements of the application. A detailed cost-benefit analysis may be necessary to determine the most cost-effective option.

In general, neodymium magnets are often a good choice for applications that require miniaturization, as they can generate a strong magnetic field in a small size. This can benefit applications where size and weight are important, such as portable electronic devices or aircraft.

Ferrite magnets are also suitable for miniaturization but are generally less powerful than neodymium magnets for their size. This may make them less suitable for applications that require a strong magnetic field.

- Other Factors

In addition to miniaturization, we also need to consider other factors when selecting a magnet for an application, such as the motor’s duty cycle or the percentage of time it is working.

For example, efficiency is often a key consideration for motors that will be used in continuous-use applications, such as refrigerator compressors or air conditioner motors. Stronger magnets, such as neodymium magnets, can make for more efficient motors because they can generate a stronger magnetic field. This can help to reduce energy consumption and improve the overall efficiency of the motor.

Why Do I choose Ferrite Magnets?

- Higher Curie Temperature

Ferrite magnets have a higher Curie temperature compared to neodymium magnets. The Curie temperature is the temperature at which a magnet loses its magnetization, and ferrite magnets have a higher Curie temperature than neodymium magnets. This means that ferrite magnets can maintain their magnetization better at high temperatures than neodymium magnets.

Ferrite magnets also have a higher temperature coefficient of coercivity, which means that their resistance to demagnetization increases as the temperature rises. This can benefit applications where the magnet will be subjected to high temperatures.

However, it’s important to note that ferrite magnets lose some of their magnetic field strength at high temperatures. The rate at which they lose their magnetic field strength increases as the temperature rises.

- Natural Corrosion Resistance

Ferrite magnets are generally more corrosion-resistant than neodymium magnets due to their composition. Ferrite magnets are made from a sintered composite of iron oxide and barium or strontium carbonate, which gives them natural corrosion resistance. In most cases, ferrite magnets do not require a coating to protect them from corrosion.

Neodymium magnets, on the other hand, are made from an alloy of neodymium, iron, and boron, which can make them more prone to corrosion. As a result, neodymium magnets typically come with a corrosion-resistant coating, such as a nickel-copper-nickel (Ni-Cu-Ni) coating, which helps to protect the magnet from corrosion. This standard coating is generally very economical and adds only a small cost to the overall price of the magnet.

- Lower Cost

Ferrite magnets are made from a sintered composite of iron oxide and barium or strontium carbonate, which makes them less expensive to produce than neodymium magnets, particularly when considering the cost per unit volume of the magnet. This can make ferrite magnets a more cost-effective choice for some applications.

Choosing The Right Magnet For Our Application

Both neodymium and ferrite magnets have been used successfully in various high-tech applications, so it’s important to carefully evaluate the specific requirements of my application to select the best magnet for the job.

This may include factors such as the required magnetic properties, the operating temperature, the corrosion resistance, the ease of machining, and the overall cost. Considering these factors, we can make an informed decision about which type of magnet will best fit our application.

Here are a few examples of how unique factors for a specific application might influence the decision between neodymium and ferrite magnets:

Neodymium OR Ferrite For Speakers?

There has been much debate in the audio industry about using ferrite magnets versus neodymium magnets in speakers. Both types of magnets have been used to create high-quality audio systems, and there are proponents of both types of magnets.

Some factors need to be considered when deciding which magnet to use in a speaker. For example, the intended use of the speaker, such as whether it will be used in a home or an automobile, can be an important factor. The design of the voice coil and matching other components can also be important. Size and weight may be important considerations, particularly for small speakers found in mobile phones and headphones.

Compression drivers, used in some speaker systems, require a lot of power to drive the sound through an orifice. This can favor using neodymium magnets, which have strong magnetic properties. However, it is also possible to design compression drivers using ferrite magnets. Ferrite magnets may be a more cost-effective option for compression drivers that do not require a strong magnetic field or are used in applications where durability is important.

Neodymium OR Ferrite For Automotive Speakers?

As a designer, you may often find that neodymium magnets are a better fit for automotive speaker designs due to their compact size and strong magnetic properties. The tight spaces in automobiles often require speakers with smaller dimensions, and neodymium magnets can help to create a smaller speaker without sacrificing sound quality.

Additionally, the strong magnetic field generated by neodymium magnets can benefit automotive speaker designs, allowing for higher efficiency and better sound quality. This is particularly important in applications where the speakers will be subjected to high levels of power and must produce high-quality sound.

Ferrite magnets can also be used in automotive speaker designs, but they may not be as suitable for applications where space is limited or where high levels of power are required. Neodymium magnets may be a better choice in these cases due to their size and magnetic properties.

Neodymium OR Ferrite For Air Conditioner Motors?

In general, neodymium magnets are often used in air conditioner motors designed for continuous use due to their strong magnetic properties and ability to contribute to the overall efficiency of the motor. The high efficiency of a neodymium magnet-powered motor can lead to reduced energy use and lower lifecycle costs over the life of the motor.

In some regions, such as Asia, the energy demand is growing rapidly, leading to strict demand-side management measures. In these cases, even air conditioner motors with a relatively low-duty cycle may use neodymium magnets to achieve higher efficiency and help utilities reduce demand at peak times.

Ferrite magnets can also be used in air conditioner motors. Still, they may not be as well-suited for continuous-use applications due to their lower magnetic properties and efficiency than neodymium magnets.

Neodymium OR Ferrite For TWS Earbuds?

Neodymium magnets are generally considered a better choice for TWS due to their high magnetic field strength and ability to generate a strong magnetic field in a small size. This makes them well-suited for use in TWS earbuds, as they can produce high-quality sound and are well-suited for miniaturization.

Neodymium magnets may be more expensive than ferrite magnets, but the cost difference may be worth it for TWS applications that require a strong magnetic field in a small size. While ferrite magnets may be a more cost-effective option in some cases, they may not be as powerful as neodymium magnets for their size, making them less suitable for TWS applications requiring a strong magnetic field.

Neodymium OR Ferrite If Space and Size Constraints?

Neodymium magnets are often preferred in applications sensitive to space constraints, as they can generate a strong magnetic field in a small size.

This makes them suitable for use in a wide range of applications that require a high magnetic field in a small size, including mobile phones, earbuds, earphones, road musician speakers, small speakers, smart speakers, and many other applications.

Conclusion

We must carefully consider the specific requirements and goals of their design when deciding which type of magnet to use. Both neodymium and ferrite magnets have unique properties that make them suitable for different applications.

Neodymium magnets are the most powerful permanent magnets currently available and are well-suited for applications that require a strong magnetic field in a small size. They are commonly used in motors and generators, speakers and headphones, wind turbines, electric vehicles, and many other high-tech applications.

Ferrite magnets, also known as ceramic magnets, are not as strong as neodymium magnets, but they have a higher resistance to demagnetization and are more durable. They are often used in applications that require a lower cost or higher temperature tolerance, such as loudspeakers, refrigerator magnets, holding magnets, motors and generators, and many other applications.

We can make an informed decision and choose the most suitable magnet by weighing the pros and cons of using neodymium magnets versus ferrite magnets. As a magnet manufacturer, we’re willing to work with designers or purchasers to determine the most suitable magnet for your application.