Magnetism has played a crucial role in the development and advancement of modern smartphones. From speaker systems and vibration motors to wireless charging and sensors, magnets are used in various ways to improve these devices’ functionality and performance.

In this article, we will explore the various applications of magnets in smartphones and how they have helped shape the mobile industry as we know it today.

Applications Of Neodymium Magnets In Smartphoes

Neodymium magnets play an important role in many of the functions and features of modern smartphones, helping to make them more convenient and user-friendly.

Speaker

One of the most common applications of magnets in smartphones is in the speaker and microphone systems. Neodymium magnets, a rare earth magnet type, are often used in these systems due to their high magnetic field strength and ability to produce clear, high-quality sound. In speakers, neodymium magnets create the magnetic field necessary to move the speaker cone and produce sound waves. In microphones, neodymium magnets create the magnetic field necessary to generate an electrical current when sound waves vibrate the microphone diaphragm.

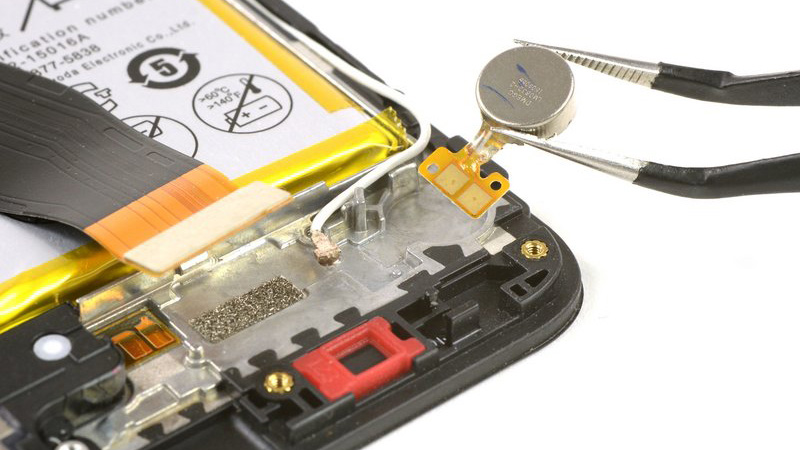

Vibration Motors

Another common application of magnets in smartphones is in vibration motors. These motors use neodymium magnets to create the vibrating motion used for haptic feedback, such as when a user receives a notification or taps the screen. Vibration motors allow smartphones to provide a more immersive and interactive user experience.

Wireless Charging

Wireless charging is another area where magnets have played a significant role in the development of smartphones. Many newer smartphones are equipped with wireless charging capabilities, which allow users to charge their devices simply by placing them on a charging pad or dock. In these systems, neodymium magnets are often used to hold the phone in place while it is being charged.

Please click Neodymium Magnets In Magnetic Wireless Charging to learn more about its application!

Sensors

Magnets are also used in various sensors found in smartphones, such as magnetometers and compasses. Magnetometers, which measure the strength and direction of magnetic fields, are used in smartphones to detect the Earth’s magnetic field and determine the device’s orientation. Compasses, which use magnetometers to determine direction, are used in smartphones to provide location and navigation services.

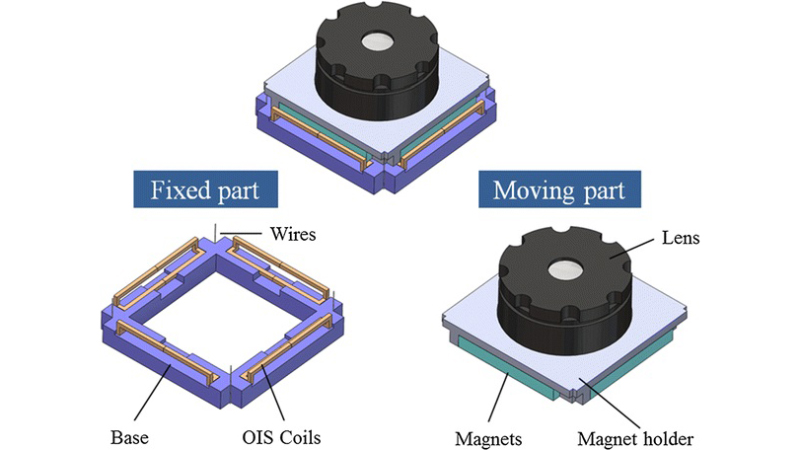

Camera Lenses

Finally, magnets are used in the focusing mechanisms of some camera lenses in smartphones. In these systems, neodymium magnets move the lens elements and adjust the camera’s focus. This allows smartphones to capture clear, high-quality images with wide focal lengths.

What Makes Neodymium Magnets Well-suited For Smartphones?

Neodymium magnets are well-suited for use in smartphones for several reasons. These include:

- Small size and lightweight: Neodymium magnets are small and lightweight, making them easy to incorporate into smartphones. This is important because smartphones are designed to be portable and easy to carry, and the use of small, lightweight magnets helps to maintain this design goal.

- High magnetic strength: Neodymium magnets have a very high magnetic strength for their size, making them ideal for applications where a strong magnetic field is needed in a small space. This makes them particularly useful in smartphones, where space is at a premium.

- Corrosion resistance: Neodymium magnets are resistant to corrosion, which makes them durable and long-lasting. This is important in smartphones, which are subjected to various environmental conditions and may be exposed to moisture and other corrosive substances.

- Cost-effective: Neodymium magnets are relatively inexpensive, making them a cost-effective choice for smartphones and other electronic devices.

- Versatility: Neodymium magnets can be used in a variety of applications within smartphones, including speaker drivers, motor drives, and sensors.

- Durability: Neodymium magnets are also highly durable, making them suitable for use in devices subjected to wear and tear over time.

Which Grade Of NdFeB Magnet is Used In Smartphones?

N48 and N52 magnets are commonly used in smartphones and other electronic devices because they offer a strong magnetic field in a small volume, making them well-suited for use in compact devices where space is limited.

What We Take Care of During The Manufacturing Process?

we produce high-quality NdFeB N48 magnets using detailed processes.

Precise Cutting Process

To minimize material loss during the cutting process, we use highly precise wire-cutting equipment that utilizes extremely thin wires. This helps to reduce the amount of material lost during the cutting process, known as kerf losses. Minimizing kerf losses is important because it can help reduce the magnets’ overall cost by conserving material and reducing waste.

In addition to minimizing kerf losses, it’s also important to ensure that the wire-cutting equipment is accurately aligned and produces consistent cuts to ensure that the magnets meet the required specifications. This may involve regularly calibrating the equipment and using quality control measures to verify the dimensional accuracy of the magnets.

Dedicated Grinding Process

We need to minimize waste and variability at every step of the process to produce high-quality components at a low cost, especially for cost-sensitive applications such as smartphone magnets. This may involve implementing lean manufacturing principles and optimizing the production process to reduce waste and improve efficiency.

We use dedicated grinding equipment to produce tiny parts with extremely tight tolerances. Grinding is a machining process that involves using abrasive materials or tools to remove material from the surface of a workpiece to achieve a precise shape or finish. Using dedicated grinding equipment, we can produce millions of small parts with precise dimensions and shapes that meet the required tolerances.

Nickel-Copper-Nickel Plating

Coating the magnets with a layer of nickel-copper-nickel electroplate can help to improve their corrosion resistance and durability. This can be done in our in-house plating facilities, allowing us more control over the coating process and ensuring that the magnets are coated to the required specifications.

We use special proprietary techniques to create a textured surface on the magnets that are conducive to adhesion. This can help ensure that adhesives stick effectively to the magnets when applied during downstream processes, such as smartphone assembly or other electronic devices. A textured surface can also improve the grip and handling of the magnets, making them easier to handle during the manufacturing process.

100% Quality Inspection

To ensure the quality and consistency of small smartphone magnets, it’s important to implement thorough inspection and testing procedures. This may involve inspecting many critical dimensions and surface finishes ensuring that the magnets meet the required specifications.

Due to the small size of the magnets and the large volume of parts that may be produced, it may not be cost-effective to rely on human inspection alone. To address this, we invest in high-tech automatic inspection machines that systematically measure every critical dimension and reject nonconforming parts. This can help to ensure that the magnets are of consistent quality and that defects are detected and corrected before the magnets are used in the final product.

In addition to automatic inspection machines, other quality control measures such as manual inspection, testing, and statistical process control may also be implemented to ensure the quality and consistency of the magnets. By implementing a combination of inspection and testing procedures, we can ensure that the magnets meet the required performance standards and are suitable for smartphones and other electronic devices.

Our Promise

JDA Magnet Co.Ltd has established a team of specialists who strongly understand customers’ needs in the highly competitive consumer electronics market. This multidisciplinary team comprises experts in materials engineering, process engineering, surface treatment, quality engineering, logistics, and sales engineering.

This team is responsible for providing fast lead times and competitive pricing for small magnets, which makes JdaMagnet a go-to source for these components. To achieve this, the company imposes strict control on all dimensions to highly exacting tolerances and has high-yield process controls. The company also carefully selects magnet grades optimized for downstream processes and end-use applications.

By using advanced processing and inspection equipment, We’re able to provide customers with the confidence and peace of mind that every magnet will be delivered on time and according to specifications. This is particularly important for customers who rely on a reliable supply chain partner to keep their production lines running smoothly.

Overall, our team of small-magnet specialists is dedicated to earning the trust of its customers by providing top-quality parts on time and meeting their specific needs and requirements.

Conclusion

Using magnets in smartphones has played a crucial role in developing and advancing these devices. From speaker systems and vibration motors to wireless charging and sensors, magnets have allowed smartphones to provide a wide range of functions and features that have greatly improved the user experience. As technology advances, magnets will likely play a significant role in developing future smartphones and other electronic devices.