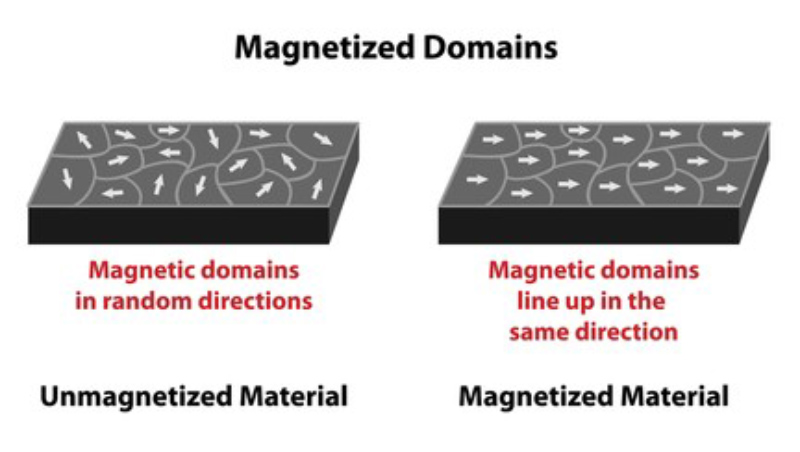

The magnetism of sintered NdFeB material, also known as neodymium iron boron, comes from its crystal structure. The material is composed of tiny crystals, each of which has a magnetic moment due to the alignment of the electrons within it. When these crystals are aligned in the same direction, the overall magnetism of the material is enhanced.

This alignment is achieved through the process of magnetization, which involves exposing the material to a strong external magnetic field. Once the material has been magnetized, it will retain its magnetism even after the external magnetic field is removed.

“Magnetization” is the key step to obtaining the magnetism of sintered NdFeB material, therefore, we have to understand the magnetization direction.

Magnetization Direction

The direction of magnetization refers to the orientation of the magnetic moments of the atoms or molecules within a material, and it determines the position of the north and south poles of a magnet. Permanent magnets, such as neodymium and cobalt samarium magnets, are made from materials that are easily magnetized and have a strong, stable magnetic field. These materials have a crystal structure that allows them to retain their magnetization even after the external magnetic field has been removed.

The direction of magnetization is an important factor in determining the strength and stability of a magnet. In general, magnets with their magnetization oriented in the direction of the applied field are stronger and more stable than magnets with their magnetization oriented antiparallel to the field. This is because the magnetic moments of the atoms or molecules are more strongly aligned with the applied field, resulting in a stronger overall magnetic field.

Can The Direction Be Changed Once Magnetized?

Neodymium magnets are powerful magnets that are formed with a preferred magnetization direction. This direction is established during the manufacturing process when the magnets are either pressed in the presence of a magnetic field or undergo a process called die upsetting, which orients the magnetic domains in a specific direction. The magnets are then magnetized at a later stage in the manufacturing process. Once a neodymium magnet has been made and magnetized, it can only be magnetized in the direction that was established during the manufacturing process.

It is not possible to change the magnetization direction of a neodymium magnet after it has been made.

Why Must Neodymium Magnets Have A Preferred Magnetization Direction?

Neodymium magnets are made with a preferred magnetization direction in order to maximize their magnetic strength. If they were magnetized in any direction, they would not be as strong. The strength of a neodymium magnet is determined by the alignment of the magnetic domains within the magnet, and the preferred magnetization direction is the direction in which the magnet will produce its strongest magnetic field.

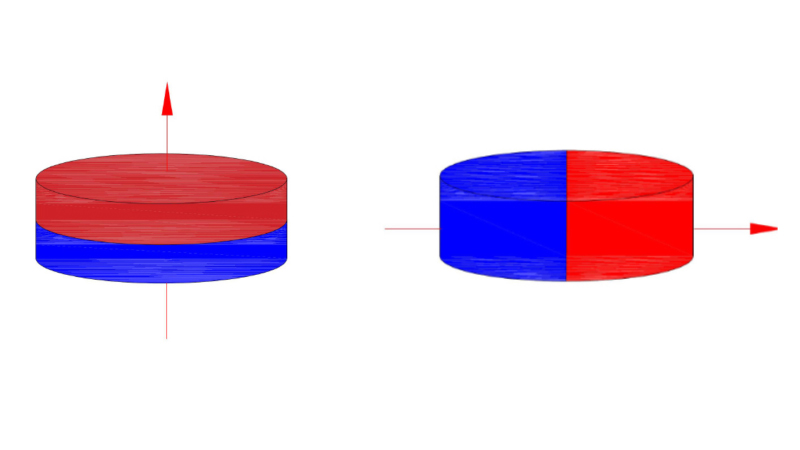

What Is The Difference Between Axial And Diametrical Magnetization?

In axial magnetization, the magnetic field is aligned along the axis of the magnet. This means that the north pole and the south pole are located at opposite ends of the magnet.

In diametrical magnetization, the magnetic field is aligned perpendicular to the axis of the magnet. This means that the north and south poles are located on opposite sides of the magnet, rather than at opposite ends.

Both axial and diametrical magnetization can be used to create magnets with different properties and uses. For example, axial magnetization is often used in motors and generators, while diametrical magnetization is often used in sensors and magnetic bearings.

Single-pole Magnetization

Single-pole magnetization refers to the process of magnetizing a magnet with just a single north and south pole. This is the most common type of magnetization and is the way that most magnets are made.

In single-pole magnetization, a magnet is magnetized by exposing it to a strong magnetic field. The magnetic field causes the atoms in the magnet to align their magnetic moments in the same direction, creating a north and south pole. The strength of the magnet is determined by the number of atoms that are aligned in this way, as well as the type of material the magnet is made of.

1. Ring-shaped single-pole magnetization.

2. Disc-shaped single-pole magnetization.

3. Block shape single-pole magnetization.

4. Arc shape single

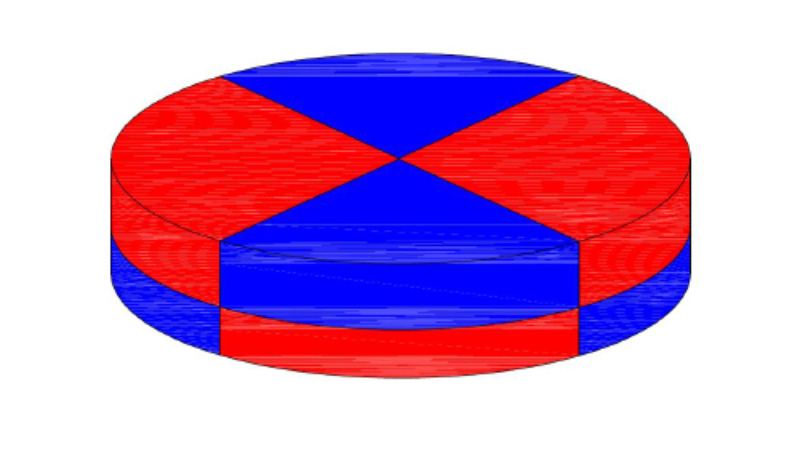

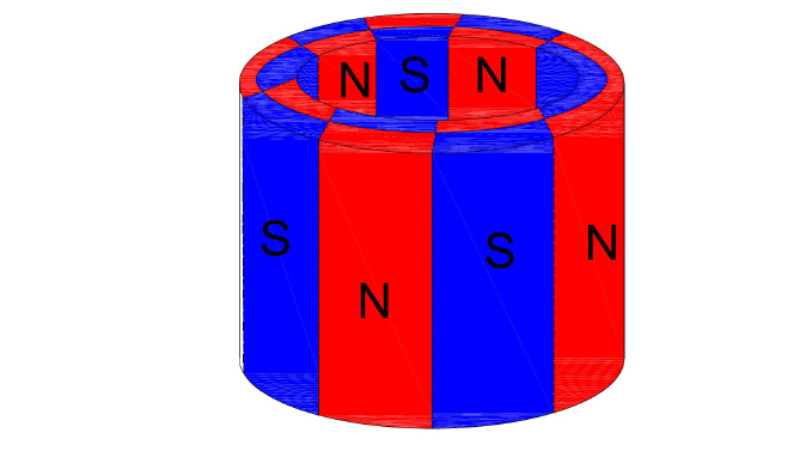

Multi-pole Magnetization

In multi-pole magnetization, a magnet is magnetized with multiple magnetic poles rather than just a single north and south pole. This can be achieved by magnetizing a magnet in a specific pattern that creates multiple poles, or by attaching multiple magnets together in a specific configuration.

Multi-pole magnetization is used in a variety of applications, including in electric motors, generators, and magnetic resonance imaging (MRI) machines. In electric motors and generators, multi-pole magnetization can improve the efficiency of the device by allowing for more precise control of the magnetic field. In MRI machines, multi-pole magnetization is used to create a strong, uniform magnetic field that is used to image the body.

There are several methods that can be used to create a multi-pole magnetization pattern, including pole saturation, pole shading, and Halbach arrays. Pole saturation involves magnetizing a magnet in a specific pattern that creates multiple poles, while pole shading involves partially magnetizing a magnet to create multiple poles. Halbach arrays are a type of multi-pole magnetization pattern that are created by attaching multiple magnets together in a specific configuration.

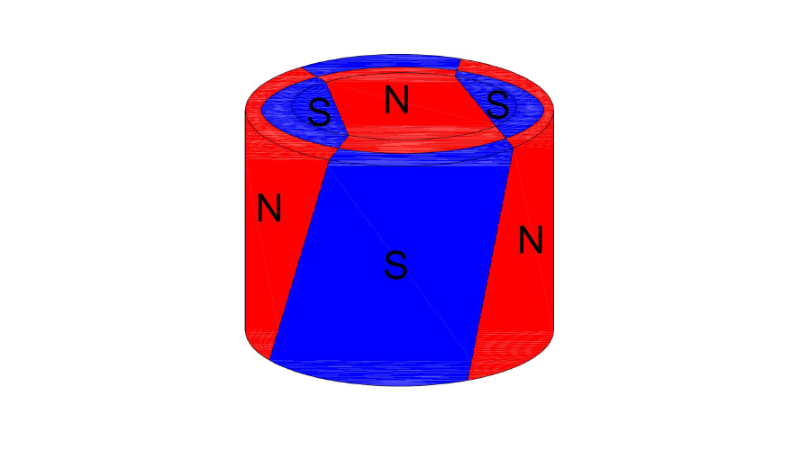

1. Multi-pole axially magnetized: A type of magnetization in which a magnet has multiple north and south poles that are aligned along the axis of the magnet.

2. Multi-pole radially magnetized: A type of magnetization in which a magnet has multiple north and south poles that are aligned around the circumference of the magnet, rather than along its axis.

3. Multi-pole diametrically magnetized: A type of magnetization in which a magnet has multiple north and south poles that are aligned along the diameter of the magnet, rather than along its axis or around its circumference.

4. Multi-pole skewed magnetization: A type of magnetization in which a magnet has multiple north and south poles that are aligned at an angle to the axis or circumference of the magnet.

Methods To Magnetize Permanent Magnets?

There are two methods generally used to magnetize permanent magnets: Static magnetization and pulse magnetization.

Static Magnetization

Static magnetization is the process of magnetizing a permanent magnet by applying a strong magnetic field to it while it is in a stationary state. This can be done using a coil of wire or by placing the magnet in a strong external magnetic field.

Here’s a more detailed explanation of the process of static magnetization:

- The magnet to be magnetized is placed in a coil of wire or in a strong external magnetic field. The magnet can be any shape or size, as long as it fits within the field.

- A current is passed through the coil of wire, or the magnet is placed in an external magnetic field of sufficient strength. The field is applied to the magnet for a period of time, typically a few minutes to a few hours.

- The atomic dipoles within the magnet align themselves with the field, causing the magnet to become magnetized.

- The process is repeated as needed to achieve the desired level of magnetization. The intensity and duration of the field can be adjusted to control the strength of the magnetization.

- Once the magnetization process is complete, the magnet is removed from the field. The resulting magnetization is permanent unless the magnet is subjected to an even stronger opposing field or is physically demagnetized through heating or mechanical stress.

Static magnetization is a common method for magnetizing permanent magnets, as it is simple and efficient. It is often used in the production of permanent magnets, as well as in research and development to study the properties of magnets and to test the performance of magnetic materials and devices.

However, it’s important to note that static magnetization may not be effective for certain materials, such as hard ferromagnetic materials like steel or aluminum, which are difficult to magnetize using static methods. In these cases, pulse magnetization or other methods may be used to produce stronger magnetization.

Pulse Magnetization

Pulse magnetization is a process in which a magnet is subjected to a series of high-intensity, short-duration magnetic fields in order to magnetize it. This can be done using a pulse magnetization machine, which generates high-intensity fields using electrical current.

Here’s a more detailed explanation of the process of pulse magnetization:

- The magnet to be magnetized is placed in the pulse magnetization machine. The magnet can be any shape or size, as long as it fits within the machine.

- The machine generates a high-intensity, short-duration magnetic field using electrical current. The field is applied to the magnet for a brief period of time, typically a few milliseconds.

- The atomic dipoles within the magnet align themselves with the field, causing the magnet to become magnetized.

- The process is repeated as needed to achieve the desired level of magnetization. The number of pulses and the intensity of the field can be adjusted to control the strength of the magnetization.

- Once the magnetization process is complete, the magnet is removed from the machine. The resulting magnetization is permanent unless the magnet is subjected to an even stronger opposing field or is physically demagnetized through heating or mechanical stress.

Pulse magnetization is often used in the production of permanent magnets, as it allows manufacturers to produce magnets with precise magnetic field distributions and enhanced magnetic properties.

Pulse magnetization can produce stronger magnetization than static magnetization, and it is often used to magnetize hard materials such as steel or aluminum, which are difficult to magnetize using static methods. Pulse magnetization can also be used to produce multipolar magnetization, which is a type of magnetization in which a magnet has multiple north and south poles. This is achieved by applying a series of high-intensity, short-duration magnetic fields to the magnet in a specific pattern.

However, it’s important to note that pulse magnetization can also cause mechanical stress in the magnet, which can lead to demagnetization over time. Therefore, it’s important to carefully consider the trade-offs between the benefits and drawbacks of pulse magnetization when deciding on the best method for magnetizing a particular material or application.

Conclusion

In general, sintered NdFeB magnets can be magnetized in a variety of directions depending on the specific application and design requirements. It is important to carefully consider the magnetization direction when designing a device or system that uses sintered NdFeB magnets, as the direction of magnetization can significantly affect the performance of the device.