Magnet Manufacturer China Since 1998

Trusted by professionals across diverse industries for consistent performance and reliable supply, our in-house facilities ensure full control over manufacturing, quality, and delivery while providing direct factory pricing and responsive support for projects of all scales.

Tailored to Your Needs.

From size and shape to plating and magnetization, we customize every detail to perfectly fit your application.

Quality You Can Count On.

29 inspection checkpoints guarantee stable, consistent performance with every batch.

One-Stop Production.

Complete in-house processes (melting, plating, magnetizing) mean faster turnarounds and reliable quality.

No Middle Man

Factory direct competitive and fair pricing ensure you stay on budget.

One-Stop Magnetic Solution

Custom Magnets for Every Industry

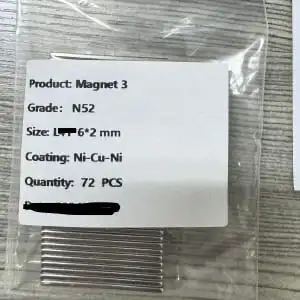

Tailored to Your Size&Tolerance

From 0.5 mm micro to 250 mm large, we cater to diverse applications with a ±0.05 mm tolerance or tighter if required.

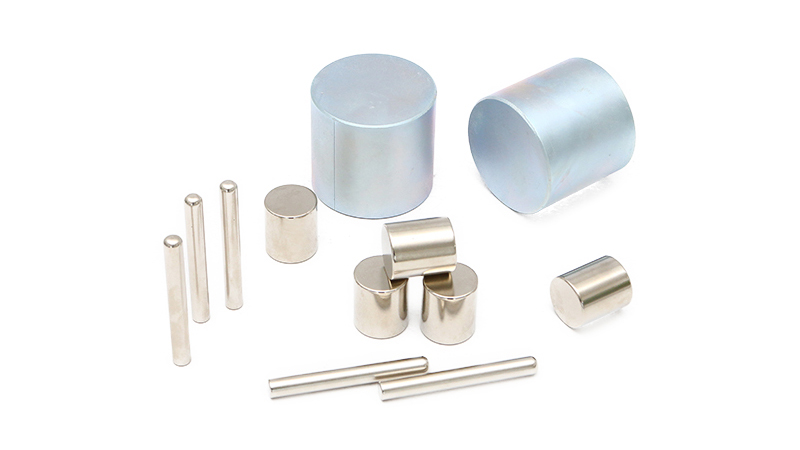

Tailored to Your Shape

We shape magnets to fit tight spaces, perfect for compact consumer electronics where every millimeter counts.

Tailored to Your Surface Plating

Popular finishes like Ni-Cu-Ni, Zinc, Epoxy, Gold, Teflon, and more protect against corrosion while enhancing appearance.

Tailored to Your Pull Force

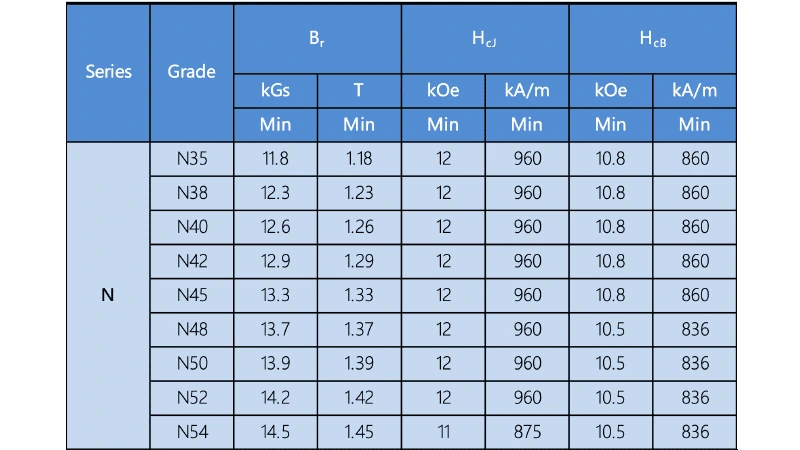

Choose from N35 through N54 to match your required field intensity, keeping performance at its best.

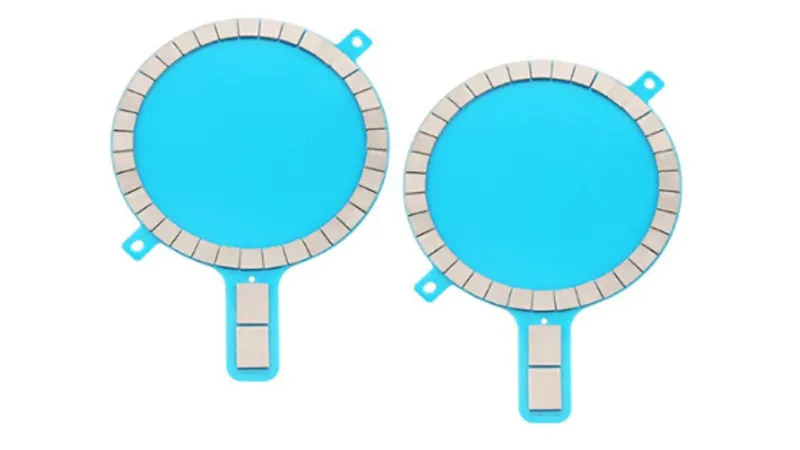

Tailored to Your N/S Direction

Single or multiple poles in axial, diametric, or radial orientations—select the ideal configuration for your design.

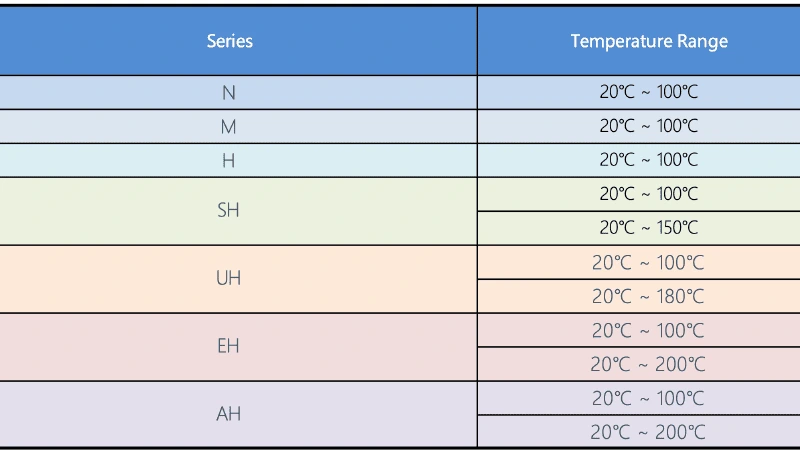

Tailored to Your Working Temp.

Support operating temp. from 80°C (N) up to 240°C (AH), ensuring reliability under demanding conditions.

Tailored Magnetic Bar

Custom magnetic filter bars designed for efficient ferrous particle removal in liquids or powders.

Tailored Magneic Filter

Custom magnetic filters for removing ferrous particles from liquids, ensuring purity and efficiency.

Tailored Magsafe Magnet

With various sizes and strengths, with both receiving and transmitting ends for optimized MagSafe charging.

Tailored Fishing Pot Magnet

Available in different sizes with corresponding pull forces to meet your specific requirements.

Tailored Magnet Base

Used as a stable base for adsorption, can be integrated with connectors for versatile applications.

Tailored Rubber Coated Magnet

Available in various sizes with corresponding holding forces, designed to fit different screw types for versatile applications.

What Sets Us Apart

Experience decades of manufacturing expertise, in-house production capabilities, and a customer-first approach—all under one roof.

Strong Capacity

5,000 tons of annual output to handle large orders effortlessly and keep your supply chain running smoothly.

Well-equiped

Full control over production—from melting, sintering, and grinding to plating—ensuring consistent quality and reliable traceability.

Fast Sampling

Prototypes in as little as 3 days to help you accelerate product development and reduce lead times.

Full Service

Seamless support through video conferences, online factory tours, and onsite inspections—guaranteeing full transparency every step of the way.

Thorough Inspections

Consistent & Reliable Quality for Every Project

Our integrated quality systems, expert staff, and cutting-edge facilities all work together to deliver consistent performance—so you can focus on your core business with total peace of mind.

29-Step Testing & Inspection

Each magnet undergoes a rigorous, multi-stage procedure to validate stability, durability, and adherence to specifications.

- Salt-Spray Test

- Cross-Cut Test (Adhesion)

- Constant Temperature & Humidity Test

- Flux Measurement

- Pull Force Test

- Demagnetization Curve Analysis

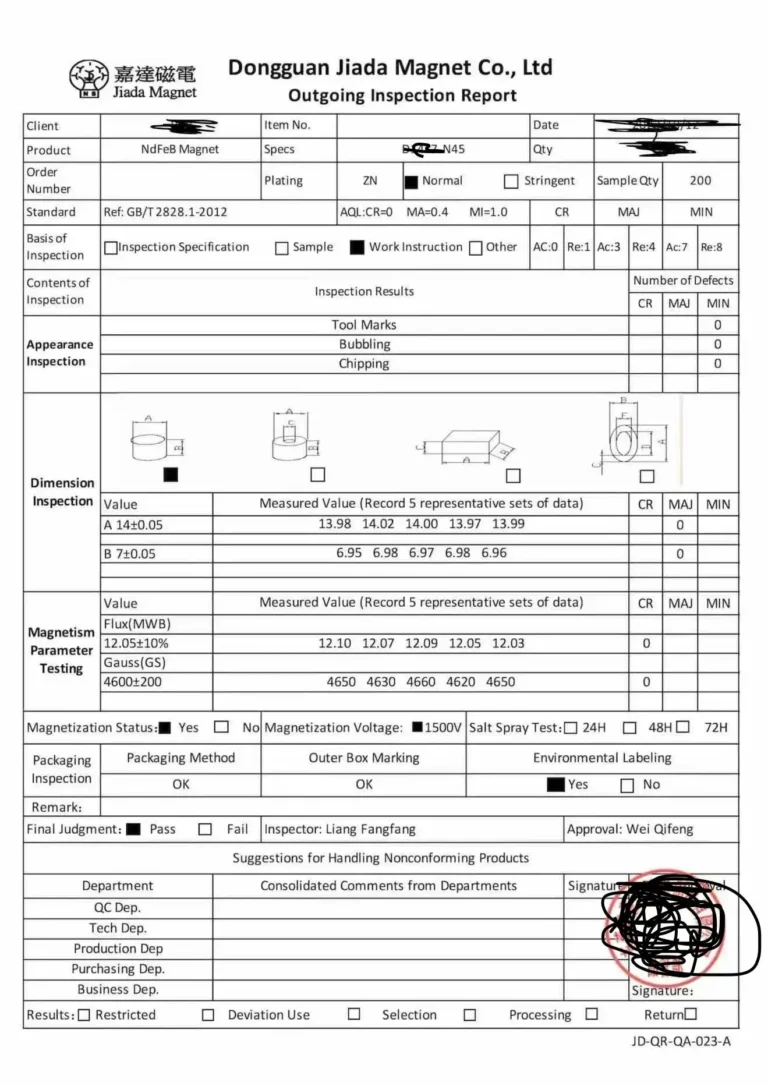

COC Report – Verified Quality from Start to Finish

A clear, detailed document confirming that every shipment aligns with the agreed standards.

- Gauss Reading

- Dimension & Tolerance

- Appearance Check

- N-Polarity Mark

- Magnetization Direction

- Coating Verification

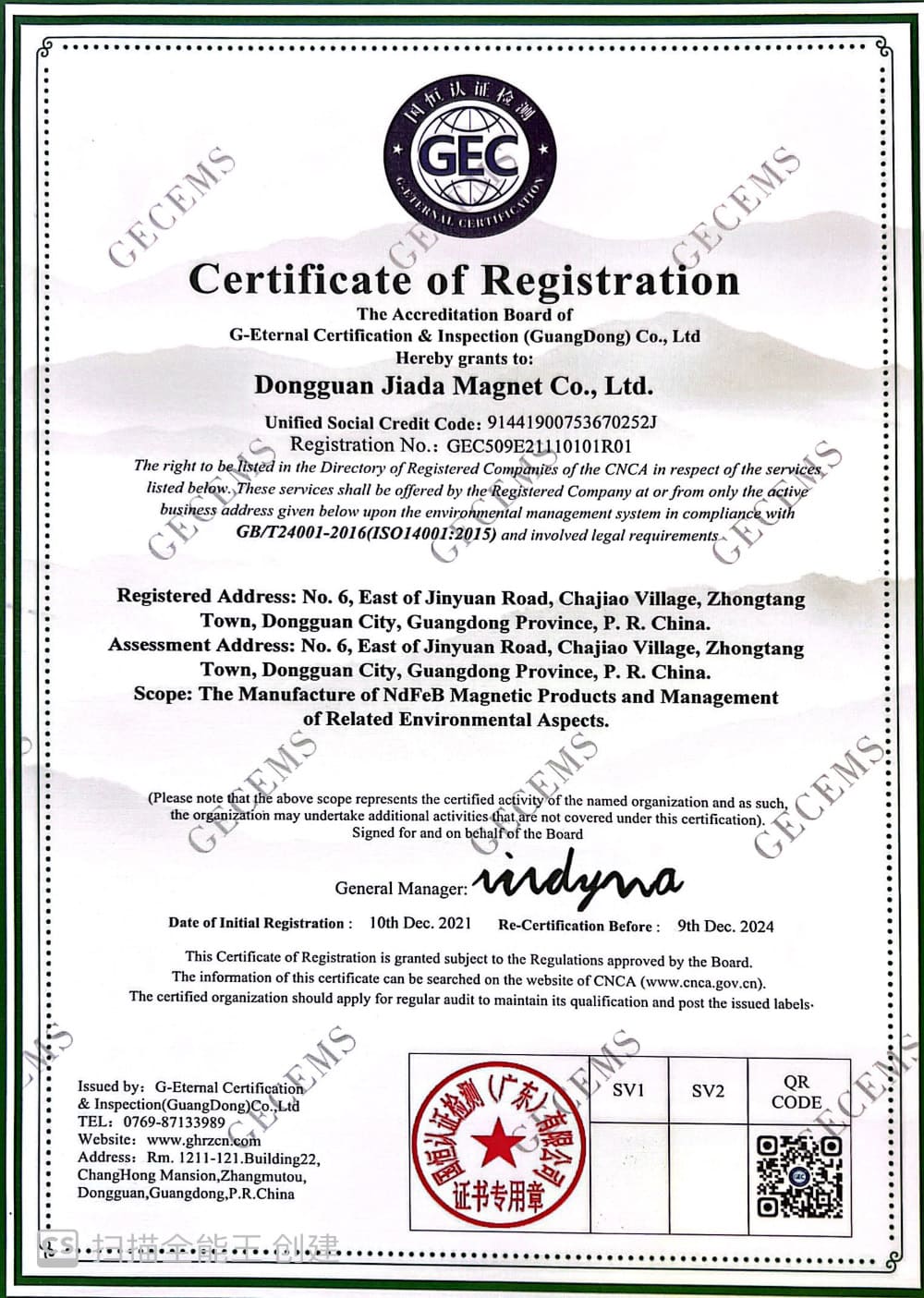

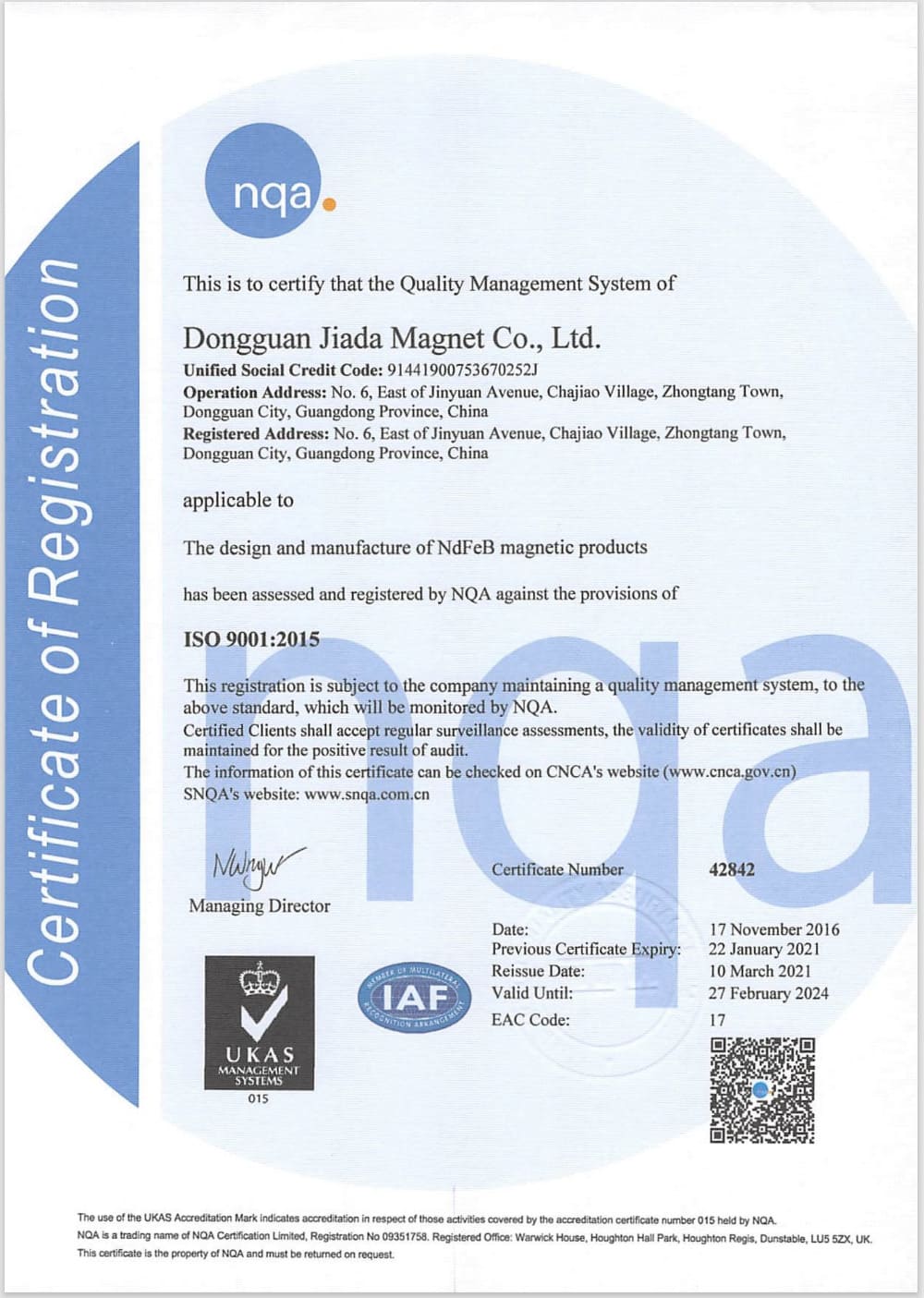

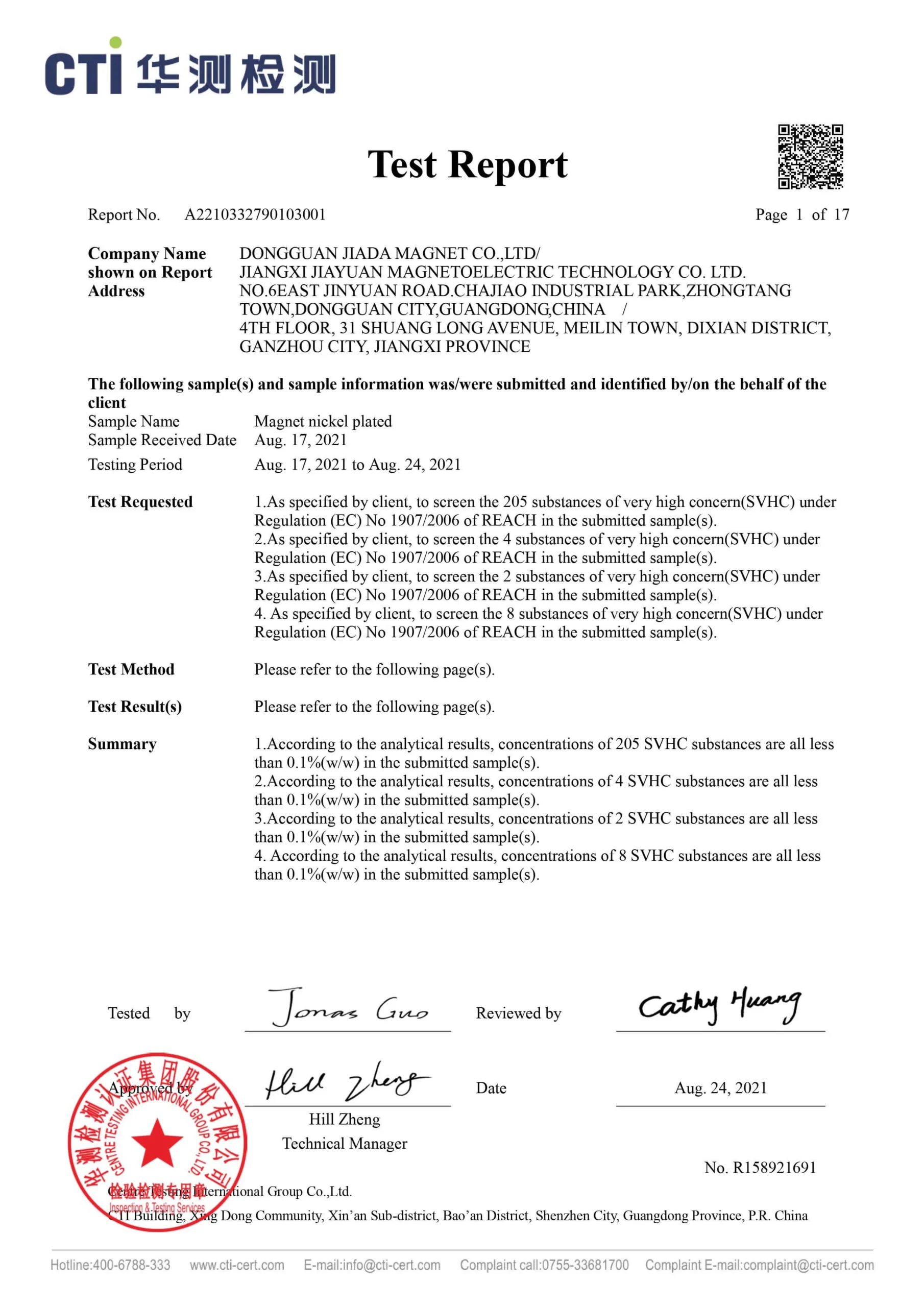

ISO Certified Quality

Backed by NQA audits, our ISO9001, IATF16949, ISO14001, and ISO45001 certifications ensure robust quality management across all processes.

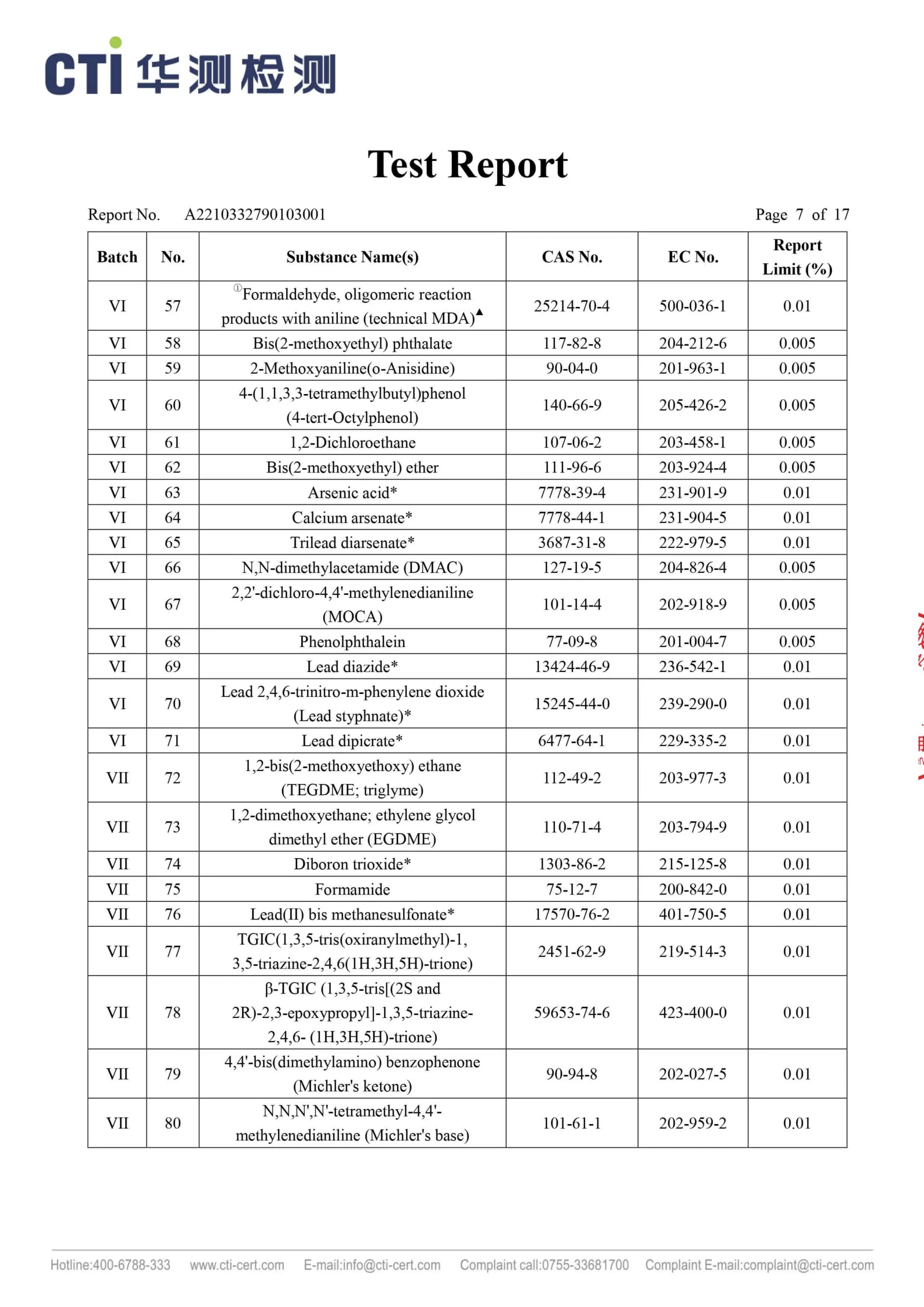

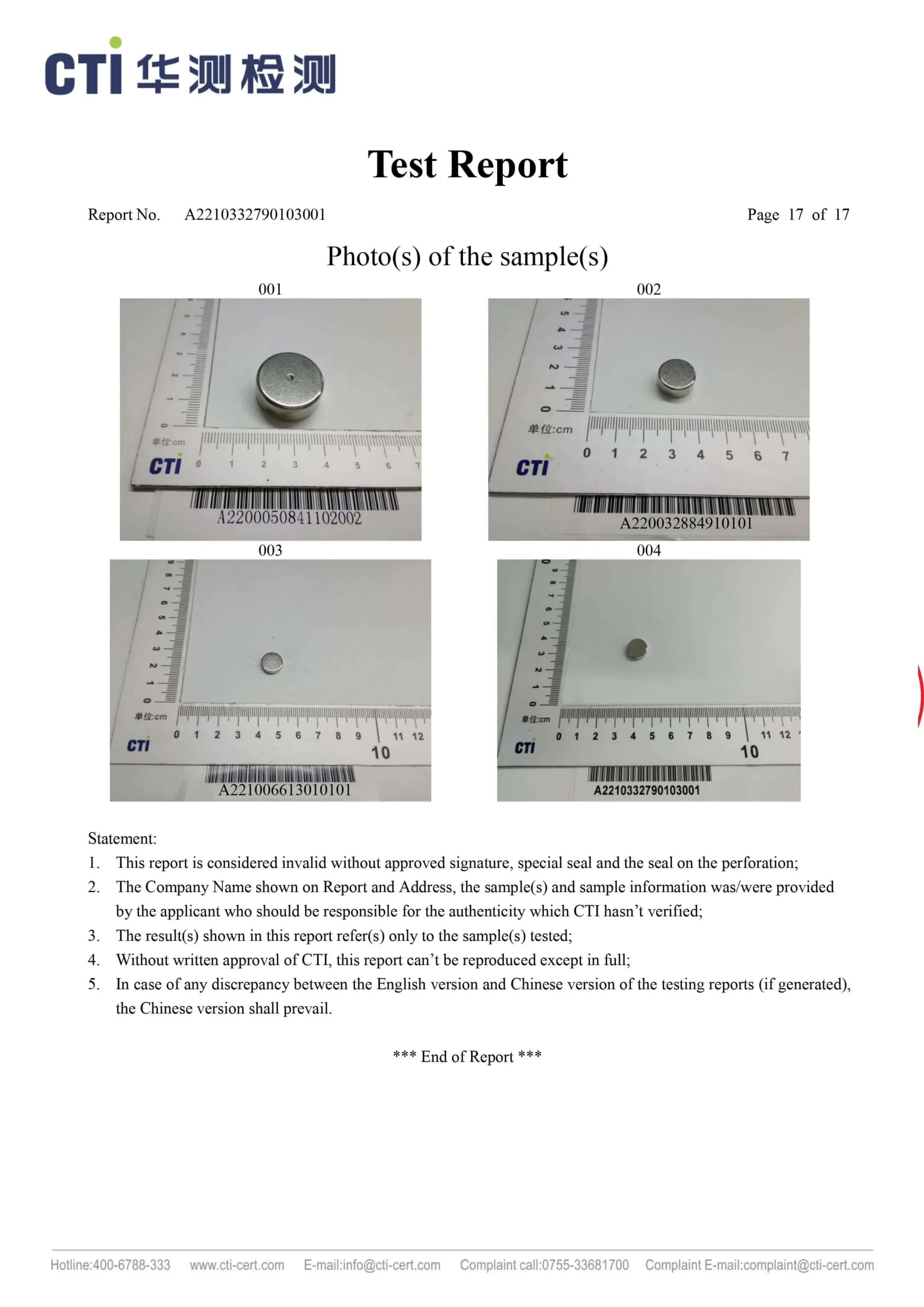

RoHS & REACH Compliance

All materials conform to RoHS and REACH standards, guaranteeing your products remain fully compliant in global markets.

Moments with Our Global Partners

From on-site visits and factory audits to busy trade show floors, our clients see firsthand the passion and expertise behind every magnet we produce.

Magnet Manufacturing Process – Precision from Raw Material to Shipment

With every stage housed under one roof, you get stable performance, quicker turnaround, and total traceability—no lengthy handovers or external dependencies.

500+

Employees

1000+

Equipments

30,000

Square Meters

200T

Monthly Capacity

Sintering

Process

We operate dedicated sintering lines, a capability not every factory can claim, guaranteeing stable performance and faster turnaround times.

- Melting & Strip Casting

- Hydrogen Decrepitation & Jet Milling

- Pressing Under External Magnetic Field

- Cold Isostatic Pressing

- Sintering & Annealing

Machining

Process

Armed with advanced slicing machines and highly efficient multi-wire cutting equipment, we produce accurate geometries with minimal material loss—so you get high-quality magnets faster.

Surface

Treatment

We offer a complete range of finishes—an advantage many suppliers outsource—ensuring better quality control and faster lead times.

Packaging & Shipping

Our magnet-safe packaging and isolation techniques meet strict transport regulations, minimizing magnetic interference and ensuring your order arrives intact.

- Express Delivery

- Sea Freight

- Air Freight

- Magnetic Shielding

Our Warehouse, Your Backyard – Always Stocked

With ample raw material inventory on hand, we respond quickly to urgent demands, helping you keep production on track.

Trusted by Thousands of Companies

The No. 1 reason to source from us? Top names in automotive, electronics, robotics, medical equipments, and more have already chosen our magnets—and they keep coming back.

Get A Quote & Request Samples

Let’s bring your ideas to life—fill out the form, and our team will be in touch within 24 hours!